Cuchillos para reciclaje de metales

Gama de productos

- Cuchillas de rotor

- Cuchillas estáticas | Cuchillas de cama

- Cuchillas de tijera de caimán

- Cuchillas de trituradora

- Cuchillos picadores

Knives For Non-Ferrous Recycling

Product Range

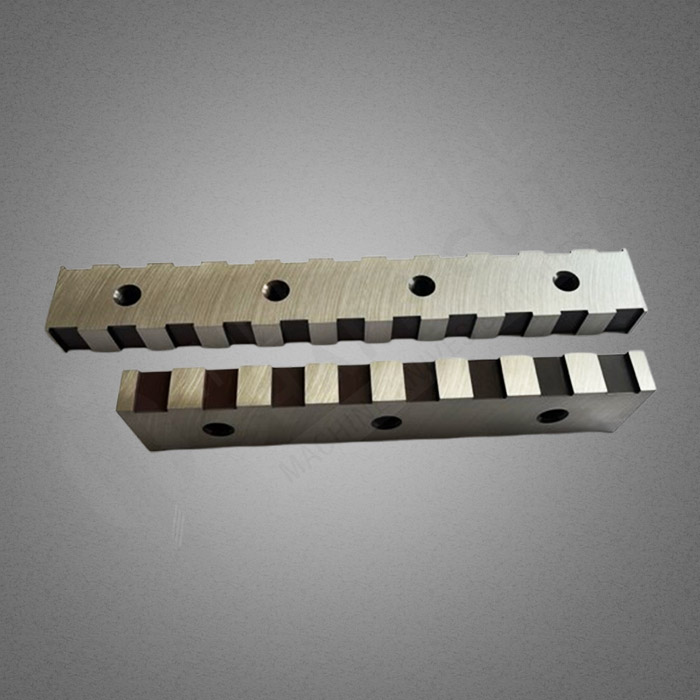

- ROTOR AND STATOR KNIVES

- ALLIGATOR SHEAR BLADES

- SHREDDER BLADES

- COUNTER KNIVES

- CHOPPER KNIVES

FAQ

What are non-ferrous recycling knives?

Non-ferrous recycling knives are heavy-duty industrial blades used to cut, shred, and size-reduce non-ferrous metals such as aluminum, copper, brass, cables, and alloys.

What applications are these knives used for?

Our knives are commonly used in:

- Non-ferrous metal recycling plants

- Shredders and granulators

- Cable and wire recycling lines

- Metal size-reduction and separation systems

What types of knives do you offer for non-ferrous recycling?

We manufacture and supply:

- Rotor and stator knives

- Shredder blades

- Chopper knives

- Alligator shear blades

- Custom knives for specific machines

What materials are your non-ferrous recycling knives made from?

Our knives are produced from high-quality tool steels and alloy steels, CNC-machined and heat-treated to deliver excellent wear resistance, impact strength, and long service life.

Commonly used steel grades are 1.2379 (D2), 1.2360 (A8 Mod)

Can these knives handle tough and mixed materials?

Yes. Our knives are designed to handle hard, abrasive, and mixed non-ferrous materials, including contaminated scrap, while maintaining cutting efficiency.

Are your knives compatible with OEM recycling machines?

Yes. We supply OEM-compatible replacement knives for many leading recycling machine brands, as well as custom-manufactured knives based on drawings or samples.

Do you offer custom non-ferrous recycling knives?

Yes. We offer custom solutions, including:

- Application-specific edge geometry

- Custom dimensions and mounting patterns

- Material selection based on recycling conditions

What are the benefits of using Industrial SharpCut non-ferrous recycling knives?

- Clean and efficient cutting

- High resistance to wear and impact

- Extended blade life

- Reduced downtime

- Reliable performance in demanding environments

What should be checked before installing non-ferrous recycling knives?

Ensure the machine is powered off and locked out, clean knife seats thoroughly, verify correct orientation, and check fasteners and torque values.

How often should these knives be inspected?

Regular inspections are recommended to monitor edge wear, cracks, and abnormal wear patterns, especially in high-load recycling applications.

When should knives be sharpened or replaced?

Knives should be sharpened when cutting efficiency decreases. Replace knives when they reach minimum safe thickness or show structural damage.

How can knife life be extended?

- Maintain proper clearances

- Avoid excessive contamination (stones, heavy steel)

- Use correct sharpening angles and cooling

- Replace knives in matched sets

What safety precautions should be followed?

Always wear appropriate PPE, handle knives carefully due to sharp edges, and never operate machines with damaged or loose knives.

Do you export non-ferrous recycling knives internationally?

Yes. We export non-ferrous recycling knives worldwide, including Europe, North America and Latin America, with export-ready packaging and logistics support.

How can I request a quotation?

Contact us via the email and share:

- Machine brand and model

- Knife dimensions or drawings

- Material type being processed

Our team will provide a technical recommendation and quotation.

Non-Ferrous Recycling Knives | Aluminum Recycling Blades | Copper Recycling Knives | Cable Recycling Blades | MTB | Eldan Metal Recycling