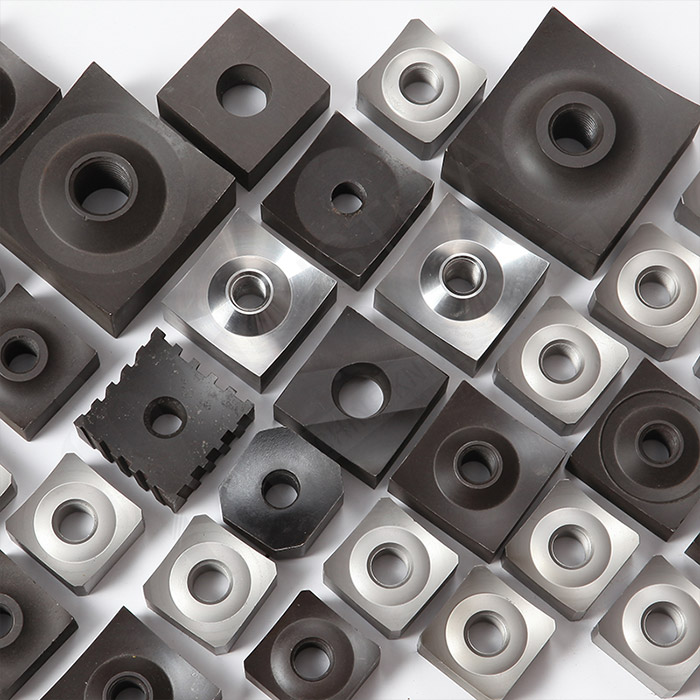

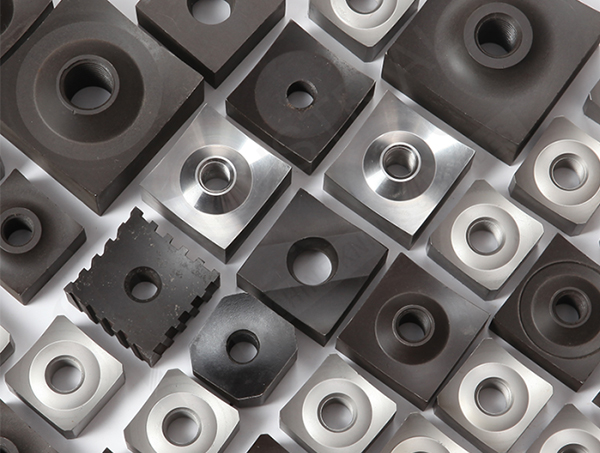

Coronas de cortadoras para reciclaje de plástico

Crown Cutters for Plastic Recycling

- Precision-engineered cutting geometry

- High wear resistance and extended tool life

- Consistent cutting performance with reduced downtime

- Suitable for high-speed plastic recycling lines

- Plastic recycling and reprocessing

- Size reduction of plastic scrap and waste

- Cutting of plastic sheets, profiles, and molded parts

FAQ

What are crown cutters?

What applications are crown cutters used for?

Crown cutters are commonly used for:

- Plastic recycling and reprocessing

- Size reduction of plastic scrap

- Cutting of plastic sheets, profiles, and molded parts

- Pre-granulation and trimming operations

What materials are your crown cutters made from?

Our crown cutters are manufactured from premium tool steels and alloy steels, CNC-machined and vacuum heat-treated to ensure high wear resistance, toughness, and dimensional stability.

Are your crown cutters compatible with OEM machines?

Yes. We supply OEM-compatible crown cutters for machines commonly used across Europe, USA and Latin America, as well as custom cutters manufactured according to drawings or samples.

Do you offer custom crown cutters?

Yes. We offer custom manufacturing, including:

- Special tooth profiles

- Custom dimensions and mounting patterns

- Material selection based on processed plastic

What are the benefits of using Industrial SharpCut crown cutters?

- Clean and consistent cutting performance

- Long service life and extended edge retention

- Reduced machine downtime

- Reliable operation in continuous recycling lines

Can crown cutters be supplied in small or bulk quantities?

Yes. We support small maintenance orders as well as bulk supply programs for recycling plants and OEMs.

Do you export crown cutters to EU, USA & LATAM markets?

How do I select the right crown cutter for my application?

Our technical team can assist based on:

- Type of plastic material

- Machine model and operating speed

- Required output and cutting performance

How can I request a quotation?

You can contact us via email by sharing your machine details, drawings, or samples. Our team will respond with a tailored recommendation and quotation.

Installation, Maintenance & Safety – Crown Cutters

Installation

- Power off and lock out the machine before installation

- Clean mounting surfaces and cutter seats

- Install cutters in the correct cutting direction

- Use recommended fasteners and tightening torque

- Check alignment and rotate the shaft manually before startup

Maintenance

- Inspect cutters regularly for tooth wear or damage

- Maintain correct cutting clearances

- Sharpen using proper tooth geometry and controlled cooling

- Replace worn cutters in sets to maintain balance

- Keep cutting area clean and free of material buildup

Safety & Usage Precautions

- Always wear appropriate PPE

- Handle cutters carefully—teeth are sharp

- Do not operate with cracked or loose cutters

- Avoid metal contamination in feed material

- Stop the machine immediately if abnormal noise or vibration occurs

Key Benefits of Proper Handling

- Longer cutter life

- Consistent cutting performance

- Reduced downtime

- Safer operation

Crown Cutters | Toothed Cutters | Crown Blades | Plastic Recycling Cutters | Shredder Blocks | Shredder cutters