Cuchillas para cortar papel

Gama de productos

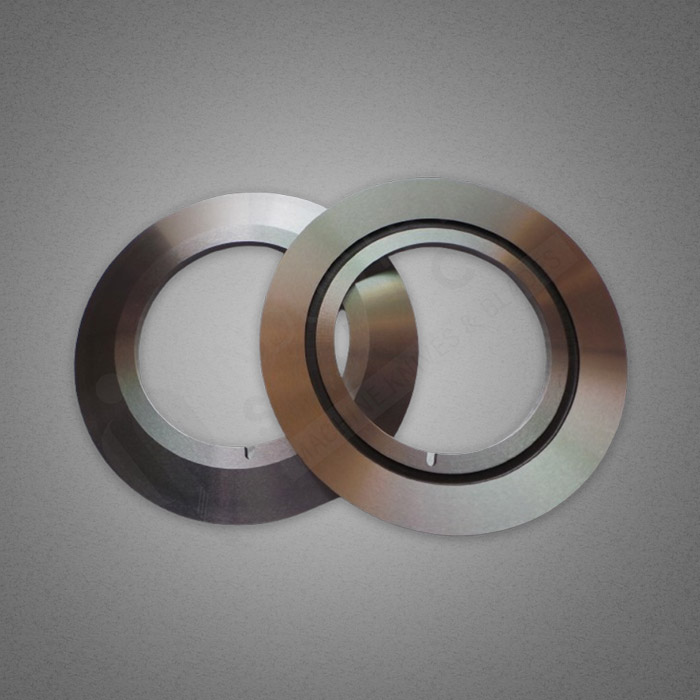

- Cuchillos de corte

- Cuchillas de guillotina

- Cuchillos laminadores

- Cuchillos recortadores

- Cuchillos para partir troncos de papel

Precision Blades for Cutting, Slitting & Trimming Applications

Product Range

- Slitting & Scoring Knives

- Sheeter & Guillotine Blades

- Trimmer & Perforation Knives

- Packaging & Carton Cutting Blades

- Log Splitter Knives

Key Advantages

- Exceptional Wear Resistance

- Extended Edge Life

- OEM-Standard Fitment

- Reduced Machine Downtime

- Short Lead Time

FAQ

What products are included in the paper and packaging category?

This category includes precision cutting and slitting knives used in paper, cardboard, corrugated board, and packaging material processing.

What applications are paper and packaging knives used for?

Our knives are used in:

- Paper cutting and slitting lines

- Corrugated board and carton converting

- Packaging and labeling operations

- Trimming, rewinding, and finishing processes

What materials are your paper and packaging knives made from?

Our knives are manufactured from high-quality tool steels and alloy steels, CNC-machined and precision-ground to ensure sharp edges, clean cuts, and long service life.

Commonly used steel grades depending upon cutting applications are 1.2601, 1.2379, 1.2067 and 1.3343

Are your knives suitable for high-speed production lines?

Yes. Our paper and packaging knives are designed for high-speed, continuous operation, delivering consistent cutting quality with minimal downtime.

Are your knives compatible with OEM machines?

Yes. We supply OEM-compatible replacement knives for many leading paper and packaging machines, as well as custom knives based on drawings or samples.

Do you offer custom paper and packaging knives?

Yes. We manufacture custom knives, including:

- Slitting knives and rotary knives

- Guillotine and shear blades

- Custom dimensions and edge geometries

What are the benefits of using Industrial SharpCut paper knives?

- Clean, precise cuts

- Extended edge life

- Reduced paper dust and waste

- Consistent performance

- Lower machine downtime

What should be checked before installing paper and packaging knives?

Ensure the machine is shut down and locked out, clean all knife holders and mounting surfaces, and verify correct knife orientation and alignment.

How often should paper and packaging knives be inspected?

Regular inspection is recommended to monitor edge sharpness, wear, and alignment, especially in high-speed production lines.

When should paper and packaging knives be sharpened or replaced?

Knives should be sharpened when cut quality decreases or dust increases. Replace knives when minimum thickness or safe wear limits are reached.

How can knife life be extended?

- Maintain correct knife settings and clearances

- Use proper sharpening angles

- Keep knives clean and free from adhesive buildup

- Avoid foreign material contamination

What safety precautions should be followed?

Always wear appropriate PPE, handle knives carefully due to sharp edges, and never operate machines with damaged or improperly mounted knives.

Do you export paper and packaging knives internationally?

Yes. We supply paper and packaging knives worldwide, including Europe, North America and Latin America, with export-ready packaging and reliable logistics support.

How can I request a quotation?

You can contact us via the email and share:

- Knife Drawing with complete dimensions

- Required steel grade of the knives

- Machine brand and model

- Cutting Application details

Our team will provide a tailored recommendation and quotation.

Paper Cutting Knives | Slitting Knives | Packaging Blades | Corrugated Cutting Knives | Scoring knife | Sheeter knife | Log splitter | Guillotine knife