Granulatormesser für Kunststoffrecycling und Zerkleinerung

- Wir sind spezialisiert auf die Herstellung und

- Lieferung von präzisionsgefertigten

- Granulatormessern für Anwendungen im Bereich

- Kunststoffrecycling, Granulierung und Zerkleinerung

Wir bieten ein komplettes Sortiment an Granulatormessern an:

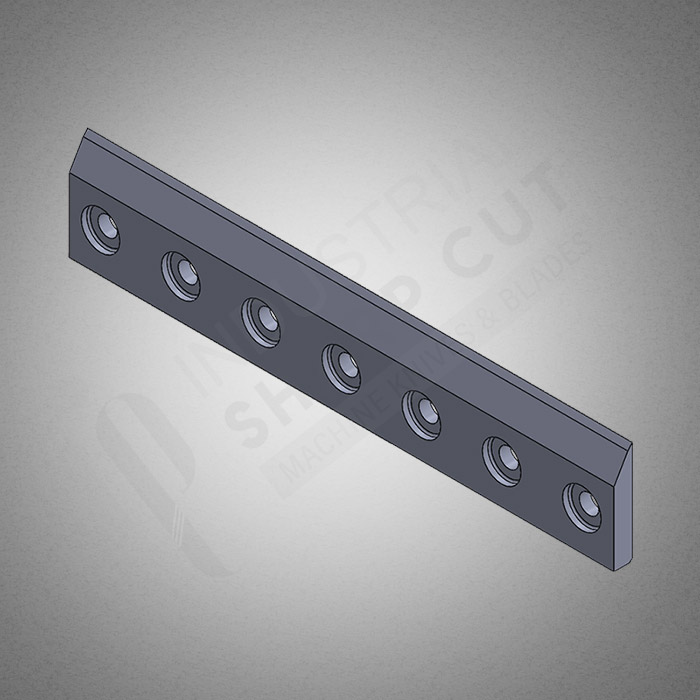

- Rotormesser | Flachmesser

- Statormesser | Flachmesser

Granulator Knives for Plastic Recycling & Size Reduction

We specialize in the manufacturing and supply of precision-engineered granulator knives for plastic recycling, granulation, and shredding applications.

Our knives are designed to deliver consistent cutting performance, long service life, and reduced downtime — making them the preferred choice for recycling plants and granulator OEMs worldwide.

High-Quality Granulator Blades for All Major Brands

We offer complete range of granulator blades including:

- ROTOR KNIVES | FLY KNIVES

- STATOR KNIVES | BED KNIVES

- DEFLECTOR KNIVES

Each knife is CNC-machined from premium tool steel and vacuum heat-treated to achieve perfect hardness, toughness, and dimensional stability.

Why Choose Our Granulator Knives?

Longer Operating Life: Superior edge retention and minimal wear even in high-volume plastic recycling operations.

Precision Fit: Manufactured to meet or exceed OEM specifications.

Custom Knife Design: We offer reverse engineering and design optimization to enhance performance and reduce power consumption.

Reduced Downtime: Engineered for clean, efficient cuts that extend intervals between sharpening.

Reduced lead time: We offer shortest delivery time in the industry, ensuring you have the tools you need when you need them.

Technical Specifications

| Type : | Straight Knives |

| Application: | Our granulator knives are suitable for processing: Plastic, Granules, Regrind, Crumb, Rubber, Flakes, Cables, Copper, Tyres, WEEE |

| Material: | 1.2379 (D2 | SKD11) |

| Size: | Made in various sizes as per machine make & model number |

| Compatibility: | We offer compatible replacement knives for ALPINE®, AVIAN®, CMG®, CONDUX®, CUMBERLAND®, DREHER®, ELDAN®, FORREC®, GENOX®, HELLWEG®, NELMOR®, PAGANI®, PALLMANN®, PREVIERO®, RAPID, REDOMA®, SHINI®, TRIA®, WEIMA®, ZENO®, ZERMA®, HERBOLD®, FOLCIERI®, GETECHA®, HOSOKAWA®, TECNOFER®,NEUE HERBOLD®, WORTEX® |

FAQ

What types of granulator knives are available?

- Rotor knives (fly knives)

- Stator knives (bed knives / static knives)

- Deflector knives (Counter knives)

- Custom granulator knives as per drawings or samples

Are your granulator knives compatible with European and Latin American machines?

What materials are used for EU-grade granulator knives?

- CNC-machined

- Vacuum heat-treated

- Precision ground

What plastics can be processed using your granulator knives?

Our granulator knives are suitable for processing:

- PET, HDPE, LDPE, PP, PS

- Plastic films and sheets

- Bottles and containers

- Pipes, profiles, and molded parts

Do you offer custom granulator knives for specific applications?

- Specific plastic types

- High-throughput recycling lines

- Noise- and dust-reduction requirements

- Energy-efficient cutting

Custom knives can be produced based on knife drawings or samples

How do your knives help reduce downtime?

- Optimized edge geometry

- Tight dimensional tolerances

- High edge retention

Do your granulator knives comply with EU quality expectations?

- Dimensional accuracy

- Material traceability

- Controlled heat treatment

- Consistent batch quality

Can you supply knives in small or large quantities?

Yes. We support:

- Small batch orders for maintenance and service workshops

- Bulk supply programs for recycling plants and OEM partners

This flexibility is ideal for both European distributors and LATAM recycling operations.

Do you export granulator knives to Europe and Latin America?

- Export-ready packaging

- Reliable international logistics support

How can I get technical support or a quotation?

You can contact us via email and share:

- Machine brand and model

- Knife dimensions or drawings

- Material being processed

Our technical team will recommend the right granulator knife and provide a competitive quotation.

Installation, Maintenance & Safety – Granulator Knives

Installation

- Power off and lock out the machine before installation

- Clean knife pockets and mounting surfaces thoroughly

- Install knives in the correct cutting direction

- Use recommended bolt grade and tightening torque

- Set correct knife-to-bed clearance

- Check rotor balance and rotate manually before startup

Maintenance

- Inspect knives regularly for wear or damage

- Maintain proper cutting clearance

- Sharpen knives using correct angles and cooling

- Replace knives in matched sets

- Keep cutting area clean and free of material buildup

Safety & Usage Precautions

- Always wear appropriate PPE

- Handle knives carefully—edges are sharp

- Never operate with damaged or loose knives

- Avoid metal contamination in feed material

- Stop the machine if abnormal noise or vibration occurs

Key Benefits of Proper Handling

- Longer knife life

- Consistent cutting quality

- Reduced downtime

- Safer machine operation

Granulator Knives | Rotor Knives | Bed Knives | Static Knives | Recycling Knives | Grinder Knives | Shredder